GMC WESTERN STATES

MOTORHOME CLUB

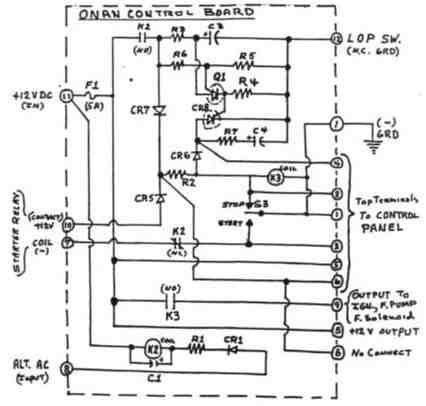

ONAN CONTROL BOARD

ONAN CONTROL BOARD

OPERATION

Prepared By: Duane M. Simmons

March 18-23, 2001

2001 Spring Roundup, Palm Desert, CA

1

Table of Contents

General Information

Motor

Generator Schematic

Circuit

Board Schematic

Start

Circuit Schematic

Run Circuit

Schematic

Stop

Circuit Schematic

LOP Circuit

Schematic

Emergency

Stop - Start Procedure

LOP Circuit Test Procedure

Remote Contol Panel Fuel

Priming Circuit

Control Board Removal

and Replacement Procedure

General Repair

Procedure

After Market Control

Boards

General Control

Trouble Shooting Guide

Trouble Shooting

Aids:

Trys to Run

with Start Switch On

Will Not Try to Run (Starter

OK)

Remote Control Panel

is Non Functional

No Starter Action

No Response to Stop Switch

General Repair Comments

Board Repair and Technical

Assistance

|

Many thanks to Len Mortimer for the

cover art work & all thiose GMC Pacific Cruisers that reviewed

this document prior to publication.

Copyright 1999

The contents of this document are based

upon personal experience gained by "Hands-On" vehicle

maintenance over many years. They are "One Man's" viewpoint

& do not prepresent authorized data pertaining to the GMC

Motorhome.

It is the Reader's responsibility to establish his/her position

associated with each subject matter before vehicle repair and/or

modifications are accomplished. |

2

ONAN

MOTOR GENERATOR

GENERAL INFORMATION

The Onan Motor Generator is powered by

a two cylinder - four cycle horizontally opposed gasoline engine.

An automotive type starter is used to start the engine. The starter

is powered by a battery located in the motor generator compartment.

A permanent magnet flywheel alternator and solid state voltage

regulator is used to charge the battery on the initial coach

configuration (dedicated onan battery, most have been upgraded

to share battery with house and are charded via the engine alternator

and AC to DC converter).

Lubrication is provided by an oil system

with a spin-on type oil filter.

The Motor Generator's electric fuel pump

draws fuel from the vehicle's main fuel tank.

A Control Circuit Board provides control

functions for operation including the following:

(a) Ignition start and stop control

(b) Fuel pump and fuel solenoid control

(c) Automatic starter disconnect

(d) Circuit fuse protection

(e) Automatic delayed los oil pressure condition shut-down

(f) Electric choke operation

(g) Remote control capability

3

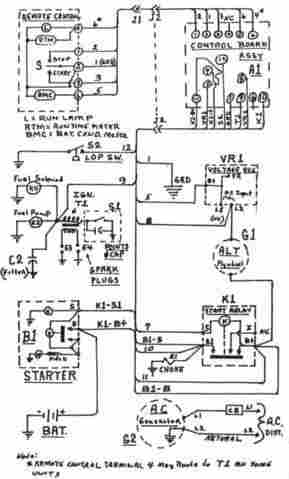

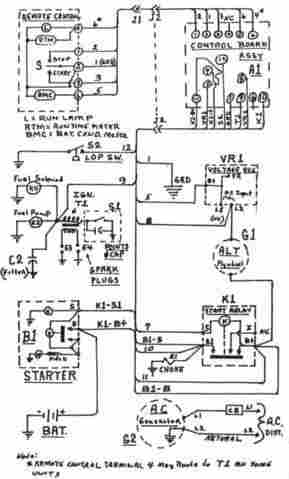

MOTOR GENERATOR WIRING DIAGRAM

Large

View

4

4

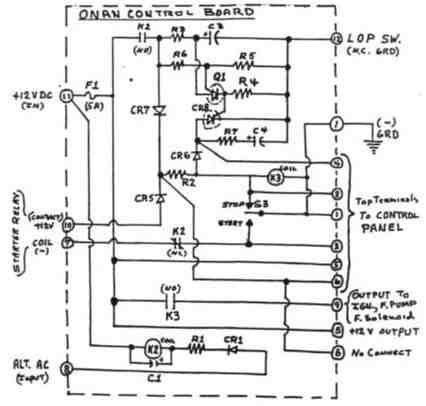

CIRCUIT

BOARD SCHEMATIC DIAGRAM

Large

View

5

5

FIGURE 1

START

CIRCUIT SCHEMATIC DIAGRAM

Large

View

6

6

STARTING CIRCUIT [Figure 1]

Pressing the "START" switch (S3

or the Remote Switch) will power the starter relay [K1] by applying

a ground through the "HOLD RELAY" contact K2a (normally

closed contact)

When the "Start" relay [K1] is

energized it activates:

(a) Starter solenoid and starter motor

[B1]

(b) Electric choke solenoid [E1]

(c) "Run Relay" [K3] thru CR5 and R2

The "Run Relay" contact [K3]

(normally open) applies power to the following:

(a) Fuel pump [E2]

(b) Fuel solenoid [K4]

(c) Ignition coil [T1]

Resulting action: Engine starts and runs

7

FIGURE 2

RUN

CIRCUIT SCHEMATIC DIAGRAM

Large

View

8

8

RUNNING CIRCUIT (Figure 2)

The output (AC voltage) of the alternator

[G1] increases as the engine speed increases. This AC voltage

is converted to DC voltage by Diode [CR1], Resistor [R1], and

Capacitor [C1] and is applied to the "Hold Relay" coil

[K2].

The "Hold Relay" [K2] is energized

when the applied voltage reaches 10 to 11 volts DC (typical).

One contact of [K2} opens to disable the start circuit ([K2a]

- See Fig. 1) and the second contact [K2b] closes to apply power

to the following:

(a) "Run Relay" coil [K3]

(b) Remote control panel

(c) The low oil pressure (LOP) circuit.

9

FIGURE 3

STOP

CIRCUIT SCHEMATIC DIAGRAM

Large

View

10

10

STOPPING CIRCUIT (Figure 3)

Pressing the "STOP" switch (S3

or Remote Switch) will short out the "Run Relay" coil

[K3] which de-energizes and removes power from the following:

(a) Fuel pump [E2]

(b) Fuel solenoid [K4]

(c) Ignition coil [T1]

Resistor [R2] limits the short circuit

current thru the "Run Relay" coil [K3] and Diode [CR7]

As the engine speed decreases, the AC voltage

output of [G1] decreases to a potential where the "Hold

Relay" [K2] de-energizes and drops out (opens). This action

removes power from the "Run Relay" coil [K3], the remote

control panel and the low oil pressure circuit. The action also

resets the [K2a] contact to the starting position for future

starts.

Resulting action: Engine stops and resets

starting circuit.

11

FIGURE 4

LOW

OIL PRESSURE (LOP) CIRCUIT SCHEMATIC DIAGRAM

Large

View

12

12

LOW OIL PRESSURE (LOP) CIRCUIT

(Figure 4)

The engine opl pressure activates the LOP

switch [S2] to an open condition (no connection) for normal engine

operation. However, if a low oil pressure condition exists, the

LOP switch activates the LOP circret by applying a ground to

control board terminal 12.

Power (+) is applied to the LOP circuit

by the "Hold Relay" [K2} after the engine starts. With

power applied and the LOP switch closed (low oil pressure condition),

the circuit is complete and capacitor [C3] starts to charge thru

resistor [R3]. When capacitor [C3] reaches the level of the voltage

divider resistors [R5 - R6], the programmable unijunction transistor

[Q1] fires (conducts) and the charge on capacitor [C3] is conducted

thru resistor [R4} to the gate of the silicon controlled rectifier

[SCR-CR8], which puts it in a conducting state [on]. Resistor

[R7} and capacitor [C4] prevents unintentional operation of the

SCR [CR8].

Typical time delay is 3 to 5 seconds

The energizing current that holds the "Run

Relay" coil [K3] during "Engine Run" is routed

(shunted) to ground via the diode [CR6], the SCR [CR8] and the

LOP switch [S2], effectively shorting out the "Run Relay"

coil [K3] which then opens (drops out), shutting down the engine

as noted in the "Stopping Circuit" description (Fig

3).

Note: LOP circuit is reset (initialized)

upon power removal

13

EMERGENCY

START / STOP PROCEDURE

Bypass circuit board (all functions except

fuse) as follows:

! Jumper

terminal 9 to 5 (fused power) - This will energize the fuel pump,

fuel solenoid and ignition coil

! Press the "Start Switch" [S3] or temporarily

jumper terminal 1 to 7 - This will engage the starter. Remove

jumper as soon as the engine starts. Note: Do not press switch

or jujper terminal 1 to 7 while engine is running.

! Remove jumper from terminal 9 to 5 for engine stop

|

CAUTION: This emergency / test operation does not provide

starter disconnect or Low Oil Pressure shutdown protection and

should not be used without monitoring the motor generator. |

For Emergency and Test Situations

Only

14

LOW OIL

PRESSURE (LOP) CIRCUIT TEST PROCEDURE

Verify board low oil pressure (LOP) circuit

operation as follows:

Engine running under normal conditions

Jumper terminal 1 to 12 and measure time required for engine

to stop

Typical delay time should be 3 to 5 seconds

Remove jumper and re-start engine

Board test complete

Circuit board is OK with 3 to 5 seconds time delay

Circuit board Malfunction if no time delay or if engine does

not stop

LOP switch and wiring test

Remove wire from board terminal 12

Measure resistance to ground of wire 12

Without engine operating, should be near zero ohms

With engine operating, should be high resistance (open)

Test complete: Attach wire to terminal 12 and start engine

Note: A malfunction LOP circuit could cause

permanent engine damage due to operation with loss of oil pressure.

15

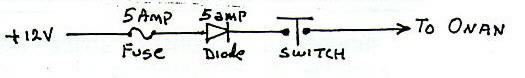

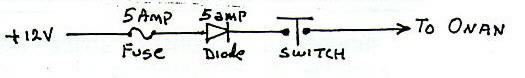

REMOTE

CONTROL PANEL FUEL PRIMING CIRCUIT

Modify remote control panel wiring with

the following:

5 amp fuse and fuse holder

5 amp diode (50prv)

Momentary switch (5 amp)

Hook-up wiring

Locate local +12 volt source and connect

fuse holder

Drill hole in panel and mount momentary

switch

Connect fuse holder to anode end of diode

Connect cathode end (with band) of diode

to switch (input)

Connect switch output to start / stop switch

terminal that is activated with +12 VDC while the Onan is running

Also wire is present between switch terminal and RTM if so equipped

Press and hold momentary switch for 10

to 30 seconds to prime carburator prior to start function

Circuit diagram:

12

CONTROL

BOARD REMOVAL AND REPLACEMENT PROCEDURE

Pull out Onan drawer and remove board metal

protective cover (Right side / 2 screws) and lightly spray board

terminals with WD-40, 2-26 or equal.

Remove wire from board terminal 11 (Input

Power), Tape wire and set aside.

! Note: Care should be taken in removing wires due

to fragile terminal design.

Remove one wire at a time and verify wire

marking of terminal number.

! Note: Wires are marked with terminals numbers.....Don't

cross them.

Verify remote control wire function (upper

terminals) before install.

! Carefully identify each wire function with ohmmeter

and an assistant to activate the remote control switch. Verify

the wires are not interchanged (crossed) or shorted to ground

within the coach.

Install control board with 4 mounting screws.

Attach each wire to board terminals using

positive ID of wire markings.

! Remove tape from wire 11 and attach to board terminal

11.

Install cable ties and board metal protective cover

Press / Hold "Start Switch" and

verify Run / Stop operation.

17

GENERAL

REPAIR PROCEDURE

Clean circuit board and terminals with

degreaser, soap and water (avoid water in the switch and relays).

Low heat to dry board

Test, isolate, remove and repair malfunctioning

component(s).

Replace CR5 diodes with 1N4004 (400 volt,

1 amp) or equal.

Due to potential damage from the choke solenoid high voltage

"Kick Back". Also replace CR1 and 6 with IN4004 diode

or equal.

Replace CR7 diodes with 1N4004 (400 volt,

1 amp) or equal

Due potential damage from CR5 failure (also replace CR1 and 6)

Replace K2 and K3 if contacts are burned

or non-functional

Apply electronic printed circuit board

protective conformal coating (acrylic resin, type AR) to printed

circuit side (bottom side) and non-terminal area of component

side (top side)...several coats

Apply anti-oxidant grease on all terminals

(protective coating)

Test and verify all circuit board functions

18

AFTER

MARKET CONTROL BOARDS

Stay away

from after market boards

No documentation of circuit

No valid trouble shooting procedure

Onan company repair centers will not work on a generator with

a bogus control board. It must be replaced with a genuine Onan

control board before repair @ $$$$$$

19

GENERAL

CONTROL TROUBLE SHOOTING GUIDE

Clean battery cables (both + and - cables

/ both ends)

! Apply corrosion prevention material to cable ends and

mating surfaces.

Remove upper board terminal wires (Leave

disconnected for test)

! Verify operation of remote control panel and that wires

are not shorted to ground.

Remove wire from board terminal 12 (Leave

disconnected for test)

! Verify oil pressure switch and wire operation (not shorted

to ground).

Remove wires (Typically 2 or 3) from voltage

regulator. Note wire location

! Tape up single terminated wire and 2X terminated wires

separately

! Permanently stow (voltage regulator is not required).

Disconnect 12 pin connector [J2]

! Clean and re-shape female sockets for round shape.

Verify fuse [F1] is 5 amp and is functional

! Terminal 5 to 1 or each fuse holder clip to 1 is +12VDC

Verify fuel present at carburator:

! Disconnect at fuel pump and jumper board terminal 9

to 5

Verify ignition functional - spark present

! Jumper board terminal 9 to 5 and make and break points

Verify voltage / resistance levels

|

Terminal |

|

|

12 to 1 |

greater than 10 ohms (starter on and

wire on) |

|

10 to 1 |

less than 0.5 volts DC |

|

8 to 11 |

26 to 30 volts AC (Onan running) |

|

10 to 1 |

greater than 10 volts DC (starter on) |

|

9 to 1 |

greater than 10 volts DC (starter on) |

|

1 to (-) bat |

near 0 ohms |

|

11 to 1 |

greater than 10 volts DC (starter on) |

20 - 21

TROUBLE

SHOOTING AIDS

TRYS

TO RUN WITH START SWITCH ON

Battery charge verified, battery cables

clean and functional, control board fuse (5a) OK, and oil level

verified

Attach jumper board terninal 9 to 5 - should

hear fuel pump running

Press start switch and Onan runs

Remove jumper and Onan continues to run

Suspect

low battery voltage between terminal 11 to 1 (with starter on)

! Must be greater than 10.5 VDC (typically 11.5 VDC

Suspect

[K1] starter relay or wiring faulty

! Must have greater than 10.5 VDC terminal 10 to 1 (starter

on)

! Temporary jumper terminal 11 to 10 and try starting

(remove jumper)

Remove jumper and Onan will not continue

to run

Suspect

low AC voltage (terminal 8 to 11) must be 26 to 30 VAC running

! Disable / disconnect Onan voltage regulator wiring

! Remove single wire and tape up without touching ground

or other wires

! Remove double wire with adapter (keep connected) and

tape up without touching ground or other wires

Suspect

remote control panel or wiring faulty

! Remove wires from upper terminals 1, 2 and 3 and try

running again.

Suspect

faulty low oil pressure (LOP) switch or wiring failure

! Remove wire from board terminal 12 and try running again

Suspect

control board faulty

! Test and / or repair board as required

Press start switch and Onan will not run

Suspect

fuel or ignition problem

! Repair as required

22

WILL NOT

TRY TO RUN (STARTER OK)

Battery charge verified, battery cables

clean and functional, control board fuse (5A) OK and oil level

verified

Attach jumper board terninal 9 to 5 - should

hear fuel pump running

Press start switch and Onan runs

! See "Trys to run with start switch on" chart:

"Onan continues to run"

Press start switch and Onan will not run

(jumper attached)

Suspect

fuel problem (probe pump wire for voltage)

! Remove carburator fuel hose at fuel pump

! Fuel must flow out of pump with jumper attached

! If not, fuel pump faulty, hose faulty or no fuel in

tank

Suspect

ignition problem

! Remove ignition point cover and hit starter so points

are closed

! Open and close points. You should have a spark

! If not, Suspect wiring, coil or points faulty

Suspect

faulty low oil pressure (LOP) switch or wiring failure

! Remove wire from board terminal 12 and try running again

! If it now runs, Suspect LOP switch or wiring

faulty

Suspect

remote control panel or wiring faulty

! Remove wires from upper terminals 1, 2 and 3 and try

running again

! If now functional, Suspect Remote Control Panel

or wiring faulty

! Probe wires from upper terminals 1, 2 and 3 to verify

Control Panel operation and wires are not crossed or shorted

to ground.

23

REMOTE

CONTROL PANEL IS NON FUNCTIONAL

Battery charge verified, battery cables

clean and functional, control board fuse (5A) OK and oil level

verified

If any of the Remote Control Panel functions

are non responsive

Suspect

the 4 wire connector faulty (located in Onan compartment floor.

! Eliminate the 4 wire connector by hard wire bypass

Press Remote Control Panel start and stop

switch - Onan should respond. If not:

Remove wires from upper board terminals

1, 2 and 3

! Jumper upper terminal 1 to 3 - Onan should start

If functional:

Suspect Remote Control Panel or wiring faulty

If non functional

Suspect control board faulty

! Jumper

upper terminals 1 to 2 (Onan running) - Onan should stop.

If functional:

Suspect Remote Control Panel or wiring faulty

If non functional

Suspect Control Board faulty

24

NO

STARTER ACTION

Battery charge verified, battery cables

clean and functional, control board fuse (5A) OK and oil level

verified

Press Control Board start switch and no

starter action

Jumper [K1] starter relay "S"

terminal (small) to chassis ground

Starter action

! Control board or wiring faulty

No starter action

! Apply +12 VDC to [K1] starter relay "S1" terminal

(large, left side)

Starter action

! [K1] relay faulty

No starter action

! Apply +12 VDC to starter solenoid "S" terminal

(slip-on terminal)

Starter action

! Wiring between [K1] and starter solenoid faulty

No starter action

! Starter faulty

Note: If starter ever stays engaged after

Onan starts:

Pull slip-on terminal wire from starter

solenoid to stop starter

! If starter stops - Suspect [K1] Relay

! If starter will not stop - Suspect starter solenoid

sticky (clean & lube)

! Remove starter battery cable to stop starter.

25

WILL NOT

RESPOND TO STOP SWITCH

Battery charge verified, battery cables

clean and functional, control board fuse (5A) OK and oil level

verified

Press control board's stop switch to find

it non functional and will not stop Onan

Remove wires from board's upper terminals

1, 2 and 3

Attach jumper between upper terminals 1

and 2

Non functional

! Suspect faulty control board

Functional

! Suspect faulty Control Board

To force stop function

Remove wire from board terminal 11, 9 or

1

26

GENERAL

REPAIR COMMENTS

Keep WATER OUT of Onan

If it gets wet, dry it out before starting (24 hours minumum)

Clean connectors and board terminals with

electrical cleaner

! CRC

Inc. #2-26 Electrical grade contact cleaner or equal at Home

Depot Home Center Electrical Dept.

Repair [J1] and [J2] with cleaner and carefully

close female sockets (back to original shape) for better contact

(hardwire if necessary)

Verify low oil pressure (LOP) circuit as

noted herein (could save an engine which is low in oil

pressure)

Before you declare the control board faulty,

verify:

Fuse [F1] (5 amp) is functional

[J1] and [J2] connector is functional (clean and repair)

Wire terminals and board terminals are functional (no broken

or shorted wires)

LOP functional (not shorted to ground)

Voltage regulator [VR1] is disabled - terminal 8 to 11 = 28VAC

+/- 2

Board

Repair and Technical Assistance

Duane Simmons

WHEN ALL ELSE FAILS

READ THE MAINTENANCE MANUAL |